As the new requirements unfold requiring the use of FFF foam concentrates, the foam pumps used to inject the new foam concentrate must be tested, designed, and applied differently.

Typically the FFF foam concentrates have a higher viscosity than the thinner AFFF’s or AR-AFFF concentrates. Fire Lion Global, the world’s leading foam pump manufacturer, has taken steps to understand how the FFF concentrates affect the foam pump itself. We tested three of the leading FFF foam concentrate concentrates on finding out how foam system design is impacted and the modifications required.

Our testing revealed that suction piping diameter and suction strainer screen hole size are crucial for selecting pump suction port size and operating rpm properly. Additionally, the method of foam proportioning or metering must be considered. Metering orifice sizes for traditional proportioners will likely require a change-out as well. Foam proportioning systems that use magnetic type flow meters insensitive to viscosity or entrained air in the liquid can accurately measure flow and inject the correct percent of concentrate offer an improved solution to accuracy and ease of use. Even if adjustments from 3% to percentages higher are quickly and easily made with an EFP type electronic foam proportioner.

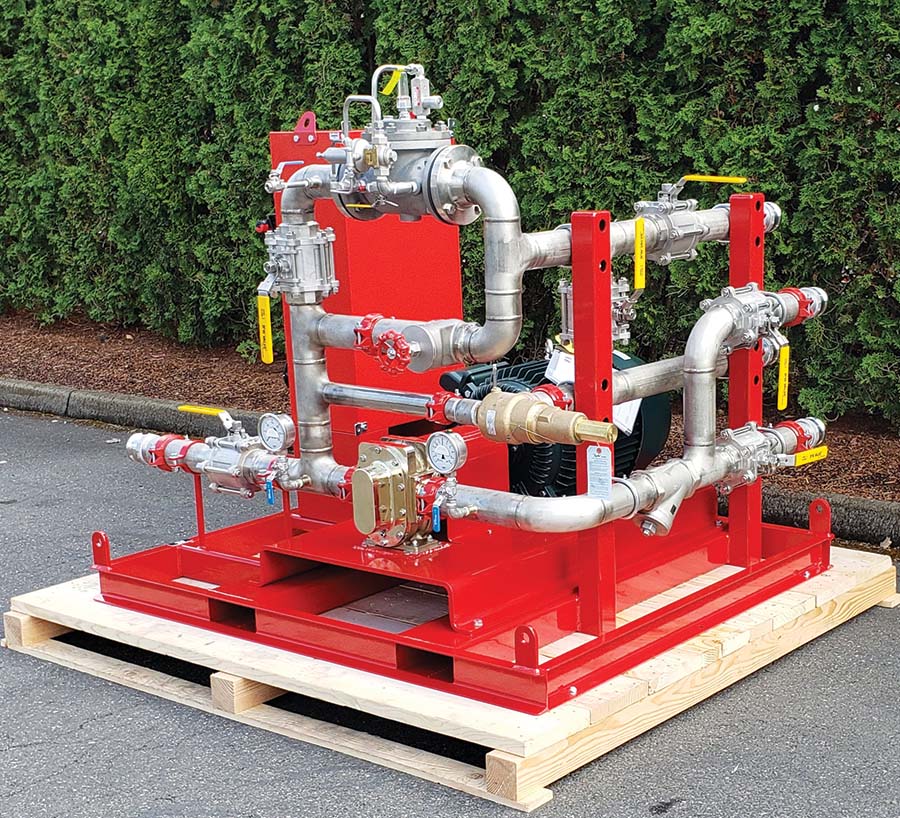

Whether using an electric motor, water turbine, diesel engine, or hydraulic motor to drive the foam pump, consideration must be given to the concentrate viscosity and how the foam pump is sized and selected. Fire Lion has built many different types of foam proportioning and ILBP pump skids and can help you design and apply the correct foam pump to your hazard. To find out more, contact us at info@firelionglobal.com.